22 Jan ACTPAC: Innovative project transforms C-C backboned plastic wastes into high value Chemicals and materials

Plastic pollution is a growing crisis, with polyethylene (PE) comprising nearly a third of all plastic waste and posing significant disposal challenges. Despite efforts, only a small fraction of PE waste is upcycled into valuable products. The ACTPAC project aims to revolutionise this by converting PE into high-value chemicals and biodegradable polyesters. This zero-waste solution promises new business opportunities and a more sustainable future.

Plastic pollution poses a significant threat to various environmental niches and ecosystems, exacerbated by the growing use and environmental leakage of plastic products. Polyethylene (PE) is the most commonly used plastic, accounting for approximately 30% of all plastics. Due to the lack of reactive groups, these plastics are typically classified as non-degradable and are commonly disposed of through incineration or in landfills. Approximately 12% of plastic waste is recycled into products of lower quality and performance. Less than 1% of PE waste is upcycled into high value products via catalytic routes. There is an evident and urgent need to develop new methods for innovative upcycling of plastic waste to achieve a paradigm shift in the plastics economy.

As a result, the project “A Complete Transformation PAth for C-C backboned plastic wastes to high-value Chemicals and materials” is funded by the European Commission as part of the Horizon Europe framework programme and the call “Industrial biotechnology approaches for improved sustainability and output of industrial bio-based processes (HORIZON-CL6-2023-ZEROPOLLUTION-01-5)”.

The main goal of the ACTPAC project is to develop a complete value-added, industry-viable path to convert PE into high-value chemicals and into PE-like but fully biodegradable polyesters. This creates a zero-waste solution for plastic waste management, keeping plastics out of the environment and reclaiming their value. The new polyester plastics from upcycled PE waste will provide opportunities for SMEs through scalable, flexible, and robust manufacturing processes for on-demand and small-volume production.

ACTPAC objectives

During a period of 48 months, the ACTPAC project aims to achieve the following objectives:

- DEVELOP new catalysts for the deconstruction of polyethylene (PE) to enable the production of value-added, biologically utilizable chemicals at reduced costs.

- ENGINEER enzymes and microbial cell systems that can produce value-added biochemicals for use in the chemical industry from biologically utilizable chemicals.

- CONSTRUCT engineered non-pathogenic yeast systems that can transform biologically utilizable chemicals into value-added biochemicals for use in the chemical industry.

- DEFINE efficient chemical routes and develop catalysts to convert value-added biochemicals into new breakthrough, biodegradable polyesters for various applications.

- CREATE a completely novel, biobased polyester that has similar or better properties as polyethylen, but is fully biodegradable, and recyclable.

- DEMONSTRATE the improved environmental and economic performances of the value-added chemicals and alternative polyesters developed in the project and achieve zero-waste management.

- BOOST the awareness on the project outcomes through communication and dissemination activities and engage main actors of the value chain as well as young professionals and early career investigators.

Impacts of the ACTPAC project

The ACTPAC project aims to make a significant impact in four key areas. First, it seeks to move towards clean, unpolluted surface water and groundwater bodies in the EU and beyond by introducing novel solutions for upcycling PE plastic waste and preventing pollution through biodegradable polymers. Secondly, it strives to strengthen circular bio-based systems, reduce CO2 emissions, and mitigate climate change by using PE waste as feedstock to produce materials that can replace current fossil-based systems. Thirdly, the project aims to substitute harmful chemicals with safer and more sustainable alternatives by advancing innovative biotechnology and other sustainable technologies to create zero-pollution bio-based solutions. Finally, ACTPAC intends to reduce the environmental impact of food systems by enhancing knowledge of the environmental and climate impacts of these systems and decreasing pollution from plastic food packaging.

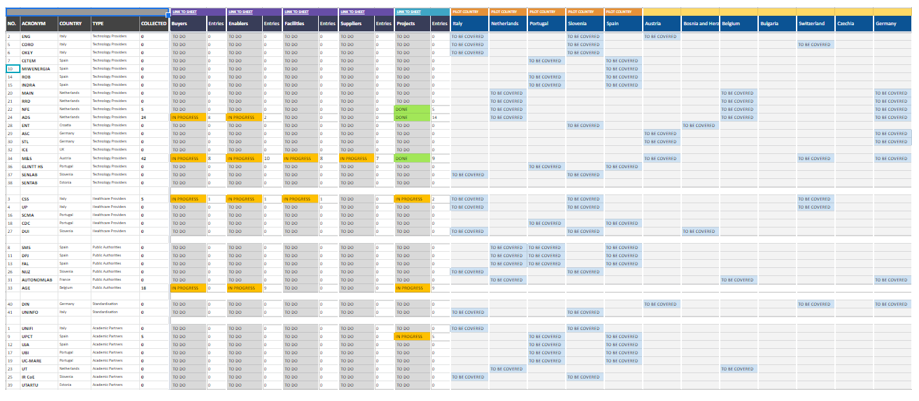

Consortium members

The ACTPAC project will be realised by a consortium of eleven partners from eight countries. The consortium comprises high-level skills and knowledge, covering the entire circular value chain, from (bio)catalyst design and optimization, to scale-up and production, to Life Cycle Assessment (LCA) and Dissemination, Communication and Exploitation.

The project is coordinated by Aarhus University (Denmark) and the partners include, next to MINDS & SPARKS GmbH (Austria), Utrecht University (Netherlands), University of Münster (Germany), National Centre for Scientific Research (France), University of Groningen (Netherlands), Plastics Technology Centre (Spain), Biolynx (Belgium), Innovaplast Biotechnology Inc. (Turkiye), B4Plastics (Belgium), and the Footwear Technology Center of La Rioja (Spain). As an addition to the consortium, the University of Bordeaux (France), which is linked to the National Centre for Scientific Research (France) will participate in the project as affiliated entity.

MINDS & SPARKS takes the lead in the ACTPAC project’s dissemination, exploitation, and communication (DEC) efforts, aiming to maximize the project’s impact. Their focus is on generating significant visibility for the project’s results, attracting key stakeholders, increasing their awareness, and actively involving them in project activities.

Links

https://www.linkedin.com/company/actpac-project/%20

Keywords

Plastic pollution, polyethylene (PE), high-value chemicals, biodegradable polyesters, zero-waste, sustainable, environment, non-degradable plastics, upcycling, Horizon Europe, value-added biochemicals, biodegradable polyesters, biobased polyester, zero-waste management, circular bio-based systems, CO2 emissions, climate change, harmful chemicals, biotechnology, pollution reduction, Life Cycle Assessment (LCA);